Unknown Facts About Best Dust Extractors

Best Dust Extractors Can Be Fun For Anyone

Table of ContentsSome Ideas on Best Dust Extractors You Need To KnowSome Ideas on Best Dust Extractors You Should KnowThe 3-Minute Rule for Best Dust Extractors3 Easy Facts About Best Dust Extractors ExplainedBest Dust Extractors Fundamentals ExplainedHow Best Dust Extractors can Save You Time, Stress, and Money.The Best Strategy To Use For Best Dust Extractors

The ideal means to discuss what this means is to go on an excursion of the course that air follows via the dirt collection system. Filthy air including particles of dust goes into the enthusiast via the ductwork.As a result, this maintains the dust from striking the filters at full rate. At the bottom of this space, accumulated dust goes down out right into a drum or hopper.

In the CMAXX, these hang vertically from the tube sheet, which is the metal sheet dividing the dirty and clean air spaces. This makes the areas that the air must go with smaller sized.

Excitement About Best Dust Extractors

Gaskets at the top of each filter seal it to the tube sheet to keep dust from slipping through. Since the pulse of compressed air goes in the reverse direction of the regular air movement, we call it a reverse pulse-jet enthusiast.

The dirt leaves of the enthusiast as well as the filters are ready to accumulate even more dirt. Beyond of the filters, filteringed system air enters the tidy air plenum. From there, it can go back into the facility or vented outside. A pulse-jet collection agency is a really reliable kind of commercial dust collection system.

Often a timer regulates the diaphragm shutoffs. To make the cleansing extra effective, the pulses can also be managed by differential pressure sensors. Differential stress sensors read the atmospheric pressure on the dirty air as well as clean air sides of the filters. The dirtier the filters are, the even more resistance they need to air undergoing them.

Top Guidelines Of Best Dust Extractors

Using differential pressure sensing units makes a pulse-jet dust enthusiast more efficient due to the fact that it decreases using pressed air. It additionally helps the cartridge filters last much longer, due to the fact that the pulses of compressed air cause damage on them. Pulse-jet dust collection systems are reliable as a result of this filter cleaning.

By making filters last much longer, a pulse-jet collection agency is the most cost-efficient shop dust collection system. In straight dust collection system layout, the filters lay on their sides and are stacked on top of each other.

In a horizontal pulse-jet dust collector, the pulse cleansing triggers dust to be blown off the filters. However, due to the fact that they're on top of each other, the dust from the leading filters drops on top of the others. In an upright pulse-jet enthusiast, the dirt that pulses off of the filters drops directly down into the receptacle.

The Best Dust Extractors PDFs

When comparing biscuits vs dowels the leading consideration is typically set you back. However woodworkers understand joint toughness, rate of arrangement and placement convenience are key considerations. Learn what joint is best for your projects in this overview.

If you specialize in metalworking, you currently recognize the importance of correct dirt collection. Not just can the steel impurities launched during use a sander contaminate the air and also unclean up your shop, yet they likewise have the possible to create harmful anonymous thermal events that can damage staff members and also devices.

To guarantee that your dirt collection process is as reliable and secure as feasible, you'll require to recognize the best methods to run and preserve these indispensable machines. At Timesavers, we generate the finest woodworking and also metalworking finishing devices in the sector.

10 Simple Techniques For Best Dust Extractors

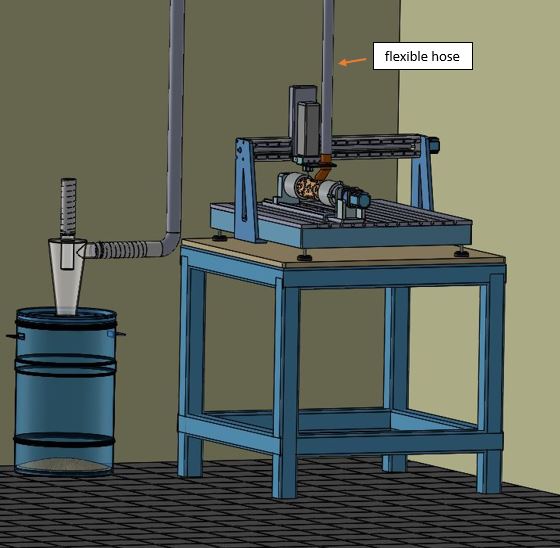

Currently that you have a strong understanding of the advantages of wet dirt collectors, let's dive a bit deeper right into just how these equipments are utilized and kept. To start, drivers will attach their commercial grinding equipment to the collector with ductwork. These pipes will carry the airalong with any kind of airborne dustinto the wet dust collector, pressing them both directly right into the water tank.

After production ends, drivers will certainly utilize an inside story to by hand draw debris up and also out of the water storage tank, leaving it got ready for the following run. Beyond these straightforward operation actions, there are two vital variables that enable wet dust enthusiasts to function appropriately. Best Dust Extractors. CFM (cubic feet per minute) determines the volume of air being relocated, and find here also static pressure (Inches of Water) is the force of the air being relocated.

Have any added concerns concerning dirt collection agencies or metal finishing in general? You can additionally contact us if you would certainly like to find out even more concerning our dust collection machines and also how they can boost the efficacy of your metalworking jobs.

The Best Strategy To Use For Best Dust Extractors

Dust is a problem in any type of interior area. It can be unsightly, can affect the respiratory system lungs of the residents. Many dust is likewise a flammable danger that require unique handling of the dust (Best Dust Extractors). This consists of unique options on the dirt collector which include explosion vents, suppression vents, and no return seclusion shutoffs.

NFPA 68 has given that 2007 required all dust to be tested to figure out the volatility of the dust. If the dirt is not check this eruptive after that the controls as specified above are not called for on dust collectors, as well as on dust collection agencies under 8 cubic feet of the unclean side of the room are excluded.

In 2014 2021 NFPA 652 mandated all firms with dirt collection systems to supply a Dust Dangers Evaluation DHA. This is a complete evaluation that consists of the dirt examination as well as details threats evaluation for that plant as well as operation. Generally done by a registered designer as well as can set you back from $6000 to $20,000.

The Single Strategy To Use For Best Dust Extractors

That is why AAir Filtration Systems designs, builds, tunes, as well as maintains premier commercial dirt collection systems for use in a variety of business areas. But just how does an industrial dirt collection system work? For a beginning, it is essential to note that there are various kinds of dirt collection systems.

Different kinds of filters as well as different degrees and also arrangements of air flow or suction power are utilized to achieve this. Commonly, the dirt from the treated air will certainly be captured or quit by the filter as the air enters contact with it. The dust will certainly then fall under a sediment catcher or it will certainly be mechanically scrubbed, wiped, shaken, or pushed right into the sediment collection area.

Then the air enters into call with a series of angled pieces of steel called baffles which reduce the air down to stop the dirt from striking the filters at a rate that would certainly harm the filters. The air is then moved right into the plenum, which is another word for the debris enthusiast mentioned over.